Plumbers have favorites and go-to’s when installing new plumbing or performing repairs. Piping options include PVC, CPVC, copper, and PEX tubing. Knowing a little about each helps you understand the difference between CPVC and PEX tubing or copper. On top of that, the debate between CPVC vs copper vs PEX rages on for reasons from price to ease of installation. We plan to cover all of this below.

Table of contents

Common Application: Replacing Galvanized Pipes

A lot of older homes we encounter have galvanized piping. Years ago, Pros used galvanized pipe as the defacto method for bringing potable (drinkable) water into the home. Now, however, it suffers from several disadvantages. For one, galvanized pipe corrodes internally over time. It gets bad enough that, after 30-40 years, water flow can be significantly restricted. As a result, many homeowners take every opportunity to replace galvanized piping whenever they redo a bathroom, kitchen, or another area which grants them access to the original piping of an older home.

Comparing Labor Costs

For years copper has been the dominant format, showing up in as much as 80% of all new construction homes in the past 30 years, but CPVC is a steady force and certainly popular with remodelers and do-it-yourselfers since it doesn’t involve sweating and soldering pipes.

Each of these products has its purpose, advantages, and disadvantages. For the most part, the difference between CPVC and PEX comes down to your familiarity with the materials and the plumbing design and functionality you’re after. You can use either CPVC, copper, or PEX tubing without any major problems. Just have them correctly installed by someone familiar with best practices for each. In deciding which is best for you, or more likely, which you should turn to when doing a remodel we’ll examine each material and explain the ups and downs.

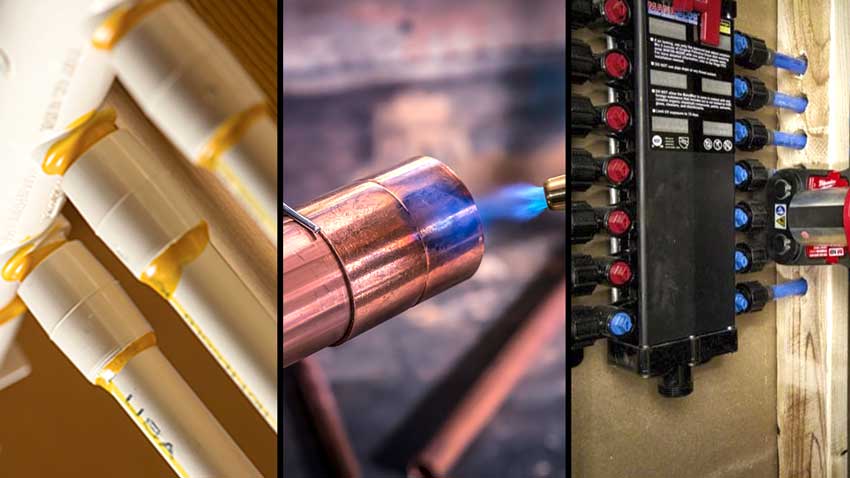

CPVC for Plumbing

CPVC piping has been in use for over 40 years and is the preferred material for amateur remodelers and do-it-yourselfers. Rated for temperatures of 140 degrees or more, CPVC is every bit as safe to use as copper piping. It has high resiliency and the ability to handle high amounts of heat. CPVC has a different outer diameter than either copper or PVC, so this is something to take into consideration when planning out your connections to legacy plumbing such as galvanized or copper. Compared to copper, CPVC is extremely lightweight and easy to install. It has a lower overall cost compared to copper, especially with the price of metals going up steadily over the past several years.

Advantages of Using CPVC

- Resistance to corrosion and abrasion

- Smooth bore for improved flow (also reduces water noise)

- High impact strength

- Easy, cost-effective installation

- Competitively priced vs. copper (and, as a result, less subject to jobsite theft)

- Lightweight

- Self-insulating to minimize thermal loss

- Flame retardant and possesses low smoke density

- Pressure rating of ~100 PSI @ 180° F, ~400 PSI at 73° F (short-term pressure rating > 200 PSI)

- Flexibility virtually eliminates water hammer (no water hammer arrestors required under normal conditions except where deemed so by local code)

- Inert to acidic soils and corrosive water supplies

- Can be buried directly under slabs with no chemical interaction with concrete

- Non-conductive

- Eliminates pressure leaks at solder joints

- Virtually no sweating or condensation

Some Considerations When Using CPVC Piping

- Subject to cracking during earthquakes

- Generally requires a 24-hour or more cure period in cold weather before pressurizing with water

To date, all national building codes have approved CPVC for use in the United States and Canada to carry potable (drinkable) water. There has been extensive testing and QC standards have been put into place to set the consistency in manufacturing for these products (ANSI/NSF-61 standards).

Copper Piping: The High-end Workhorse

Copper piping is the workhorse product of the United States. While some people hate copper for domestic use, copper has been around since the late 1920s and in 1932 the American Society for Testing and Materials (ASTM) standard B88 was created as the standard for seamless copper piping.

By the early 1980s, it has been said that the production, sale, and installation of copper water piping had already exceeded more than half a billion linear feet annually. It’s an excellent solution for home or commercial piping, provided the supplied water is kept very close to a pH of 7 (neutral).

One of the most talked-about drawbacks to the use of copper piping is the issue of pinhole leaks. Pinhole leaks, which occur most often with older homes in horizontal cold water supply lines, are a result of corrosion in the pipe with eventually disrupts the pipe wall in a non-uniform fashion, producing a leak. Possible causes for pinhole leaks include the use of water softeners, high pH, and excessive flow rates (among others).

Advantages of Using Copper Piping

- Proven, long-term durability in non-acidic installations (15-20 years)

- Biostatic – does not support bacteria growth

- Earthquake tolerant

- Fire-resistant; its high melt point (1981°F) is 5-times higher than CPVC

- Widely accepted by all building codes

- Contemporary US-Made copper pipe is 99.9% pure (copper/silver) according to ASTM specifications (note that older copper pipe may contain higher amounts of lead).

- High rated internal working pressure

- Fast “cure” time (can be pressure tested in 10 minutes)

- Can be bent to avoid obstructions, minimizing joints

- Available in annealed (soft) and drawn (hard) versions

- Small external diameter relative to CPVC

- Joints are not bulky

Disadvantages When Using Copper Pipes

- Some report of “metallic taste” to water

- Volatile pricing, subject to steep increases due to market forces (more subject to job site theft)

- Can produce “pinhole” leaks in the presence of acidic water

- Limited in some areas to use only when water pH is less than 6.5 – 6.8 (acidic)

- Can leach lead or copper into the water supply

- The labor-intensive installation process requires a skilled plumber

- Calcium build-up can occur, constricting water flow

- Higher initial installed cost (labor and materials)

- Thermal loss – requires an insulating jacket

- Condensation can occur if not properly insulated

- Noisy at high water velocities

- Subject to water hammer at velocities higher than 5 FPS; may require water hammer arrestors to mitigate damage

- Copper joints prone to failure at high temperatures (180°F and velocities)

- Installation with a gas torch is a potential fire hazard

- Repairs difficult for DIY’ers, requiring special training and tools

Although the health side-effects of copper plumbing are relatively unheard of, the EPA ironically lists copper as a contaminant in drinking water. The maximum permissible level is 1.3 mg/L. New copper installations, which tend to bleed off more copper initially, coupled with aggressive or acidic water can be a toxic combination. Older copper installations, including faucets, may also contain higher levels of lead, including lead solder which was commonly used before 1987.

PEX Tubing (Cross-linked Polyethylene)

PEX stands for cross-linked polyethylene. That’s a fancy way of describing the process by which this plastic pipe is manufactured. Cross-linking creates connections between the plastic’s polymer chains. Manufacturers use three different ways to manufacture PEX tubing using this cross-linking process. PEX A, B, and C represent the different methods (as opposed to “grades” of PEX). PEX tubing uses an extrusion process, heating the material under pressure and eventually pulling the tubing out through a die.

Though in existence since the 1960s, PEX tubing has only been in commercial use for US plumbing applications since the ’80s. Many installers like PEX because it is flexible (1/2-inch can take a 90-degree bend in just an 8-inch radius!) and can typically be run from the supply to the destination in a single run. As you can imagine, this saves considerable time during installation over copper or even CPVC.

Why Use PEX Tubing?

PEX handles a wide temperature range, from below freezing to over 180 degrees Fahrenheit, making it suitable for hot and cold potable supply lines, service lines, and even hydronic radiant floor heating systems. It can be installed under the slab and can even penetrate the slab directly with only a sleeve.

PEX is typically ran in “home-run” configurations where the supply lines are split into multiple hot and cold runs and sent out from a single source to each destination spigot, fixture or tap. This also means that the homeowner can shut down just a single line (hot or cold) in order to make a repair or modification to fixture – all without disrupting water flow to the rest of the house.

In short, PEX is very cool, though the newest to the scene. For plumbers, this means that if you can bill by the job you will save considerable time. If you bill by the hour, PEX (vs. copper) can seriously put a damper on your billable time—it’s far too quick to install!

PEX is available in diameters from 1/4-inch to 1-inch CTS (copper tube size) and is traditionally packaged in either coils or 20-foot straight pieces. Installation is accomplished with either mechanical or compression-style fittings.

Quick Facts on PEX

- Requires the use of brass fittings

- Some special tools are needed for installation (making it less friendly for the casual homeowner or remodeler to use)

- Extremely durable and expansion-tolerant when installed correctly

Of course, three types of PEX exist on the market, commonly referred to as PEX A, B, and C. PEX C is much less common for whole-home applications, so we’ll compare A and B (in laymen’s terms). In doing so we find some key differences.

| PEX A | PEX B | |

|---|---|---|

| Flexibility | Most flexible | Flexible |

| Attachment Method | Cold expansion | Crimp |

| Fitting Hardware | Expansion-style fitting | Insert-style fitting; Copper sleeve |

| Kink repair | Heat gun | Unrepairable |

| Flow restriction | None | Yes, inserts |

| Burst resistance | High (480 PSI) + flexibility | High (480 PSI) |

| Chlorine Resistance | Average | High |

| Manufacture Method | Peroxide | Moisture-cure |

CPVC vs Copper vs PEX Materials Comparison

We wanted to give a clear delineation in the CPVC vs copper vs PEX debate. One way to do that is to assume some facts and then create a grid. v

Let’s assume a simple configuration of two 100 foot runs of 1/2-inch pipe, each of which connects from a source to a spigot and each having to round a 90-degree bend. We won’t count any fittings or adapters on each end but merely what is required to make the end-to-end run. We did include tools where they might be specialty items that wouldn’t otherwise be in your tool kit. See below for our CPVC vs copper vs PEX table.

| CPVC | Copper | PEX Tubing | |

|---|---|---|---|

| Piping Cost | $65.60 | $206.20 | $64 (Red/Blue 100 foot rolls) |

| Fitting Costs | $0.38 | $1.00 | $0.40 |

| Misc Costs | None | Flux $7 | None |

| Required Tools | CPVC glue ($6) PVC pipe cutters ($25) | Torch ($30) Silver solder ($25) Copper tubing cutter ($9) | PEX crimper ($99) |

| Total Cost | $96.98 | $278.20 | $163.40 |

Note: Using PEX tubing in a home run configuration may cost an additional $100-$250 for the multi-port manifold that divides the incoming hot and cold and sends it to the entire home.

So Who Wins the CPVC, Copper, and PEX Tubing Contest?

Looking above, CPVC is the clear winner in terms of cost and ease of installation. PEX tubing is a clear second and actually gets less expensive once you eliminate tool expenditures. Copper is still the most expensive way to go. However, for some odd reason, Pros and homeowners still consider it the premier high-end solution. In our opinion, we’d do our own homes in PEX if we were building new construction. For older homes, we tend to convert all copper (where possible) to CPVC, and copper we only use when it means saving lots of time and energy converting to CPVC and back again (ie when repairing something in the middle of an all-copper run.

There is no definitive right or wrong answer in the CPVC vs copper vs PEX debate. You really need to understand which method and materials you or your builder chooses. In the end, you may not have much choice as a consumer.

As a tradesman, however, you could stand to save a lot of money or even get more jobs due to reduced time spent running pipes. Hopefully, this guide exposed you to at least some of the variables involved in making the choice that’s right for you.