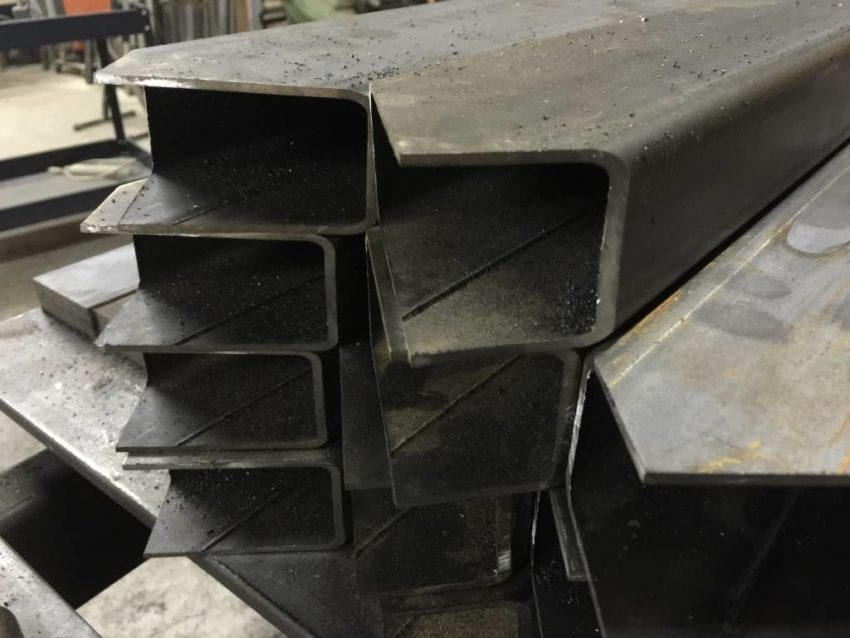

I had recently been working on some new bistro table designs that I wanted to add to my current line of hand-made furniture (www.seventeen20.com). One design, in particular, required cutting eight very consistent pieces of 2×4 steel tubing at three different angles. While brainstorming with a friend about how to make the jigs, we came to the conclusion that I just couldn’t do this consistently enough with my current wet bandsaw or abrasive chop saw. So we spent some time searching the Internet for better cutting tools that would lend themselves to jig use. We looked at everything from handheld bandsaws, to 7” angle cut-offs, to metal-cutting circular saws.

I was drawn to the Milwaukee 6370 for a number of reasons: first and foremost, I was born right around the corner in Oshkosh, Wisconsin. My blood runs cheese curd, through and through. Secondly, I don’t have enough lightning bolts on my tools. That lightning bolt always reminds me of cutting up kitchen cabinets at about 10 years old with my dad’s Milwaukee Sawzall.

As a ten-year-old, you feel like you’re dominating with a combination sub-machine gun/jackhammer/drill-saw. But most importantly, of course, are the serious and actual reasons I went for the Milwaukee 6370: the 8” blade gets a very deep cut (2-9/16”); the plunge lever makes it easy to get in and out of the jig we planned to build; the chip collection looks like the best available and will leave a clean working area for multiple cuts; and typically, circular saws are very easy to repetitively index with jigs. Trigger pulled—the 6370 is on its way.

Looking it Over

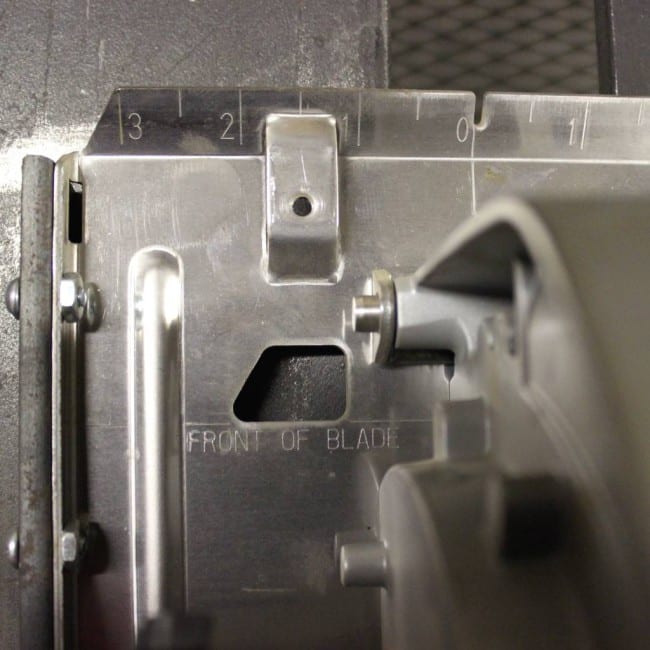

Naturally, I opted for the kit that includes a hard case (6370-21). If you’ve read any of my other reviews, you know it’s no secret that I prefer hard cases for my tools. Upon opening the case, I had lots of initial thoughts. It has a good case. The plunge lever operates very smoothly with my thumb (awesome feature). The blade guard pops on and off easily and the shoe is very sturdy and has blade point-of-entry indicators (a nice touch). Finally, the cord is very long. I like that the tool is very simple; it means that it instantly feels familiar. Milwaukee added some very innovative features on the 6370, without making it feel gimmicky or over-designed. I thought the same thing about the Milwaukee Torque Lock clamps and pliers.

Milwaukee 6370 8″ Metal Cutting Circular Saw Specs

- Power Source: 120V AC

- No Load Speed: 3700 RPM

- Amps: 13

- Max Cutting Capacity: 2-9/16″ at 90 degrees

- Blade Size: 8″

- Weight: 13.3 pounds

- Price: $319

- Warranty: 5 year

Lightning Strikes

Even though I didn’t quite have my jig finished, I had to start cutting some scrap steel as soon as I could reach a plug. And after unwrapping the cord, I felt like I could use any plug in my shop—without an extension cord! Turns out I couldn’t quite reach all of them, but I could actually reach the outlet nearest me with plenty of cord to make some cuts. I know I’ll always use an extension cord—I’ve got them coiled up all over the shop—but for some reason the long power cord on the 6370 made me feel like I just found the bonus fry at the bottom of the Chick-Fil-A bag.

I had some 2x6x¼“ steel tubing cut-offs in my scrap pile, so I figured they’d be a great place to start. Clamping a piece to the edge of my welding table, I went for a free-hand cut, straight across the 6” face. It’s always a little nerve-racking to make the first cut on a new tool. You’re never sure what to expect the moment the blade meets the workpiece.

The result? Smooth as butter. I honestly wasn’t even sure I was cutting through the steel! I looked over at my shop hand and asked, “Is it cutting through?” The cut was so clean—not a single burr—and was still cool to the touch. It was awesome. I grabbed my speed square and went for a single-handed cut against it at 90º, then at 45º. I was sold. These were by far the cleanest cuts I’d ever had out of steel. I’d better get my jig finished up.

Making a Jig for the Milwaukee 6370 Metal Cutting Saw

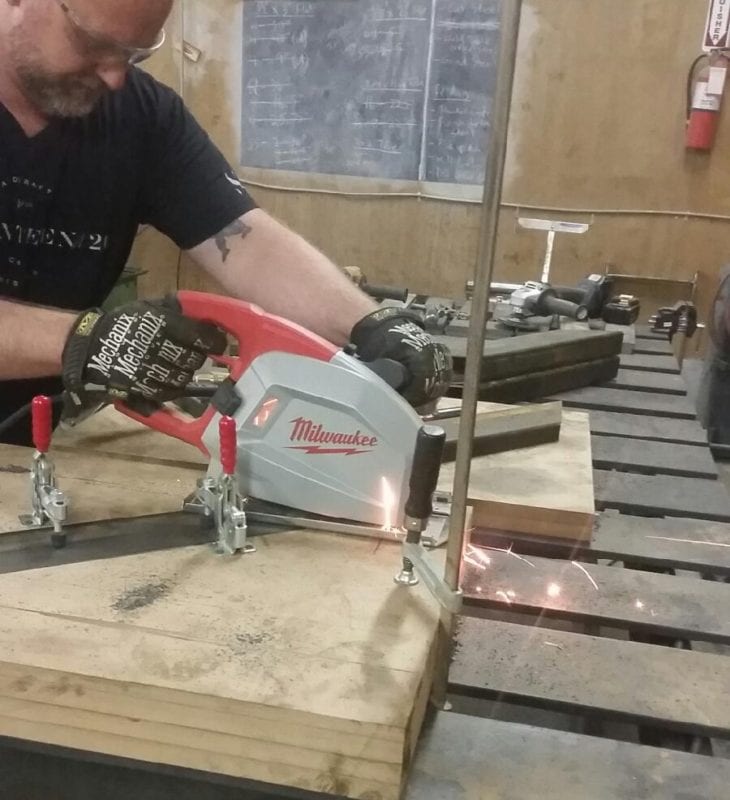

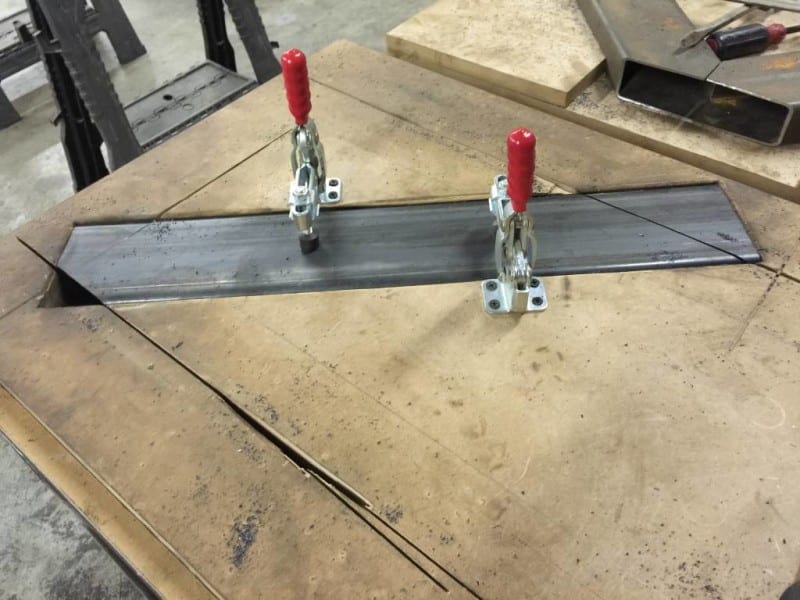

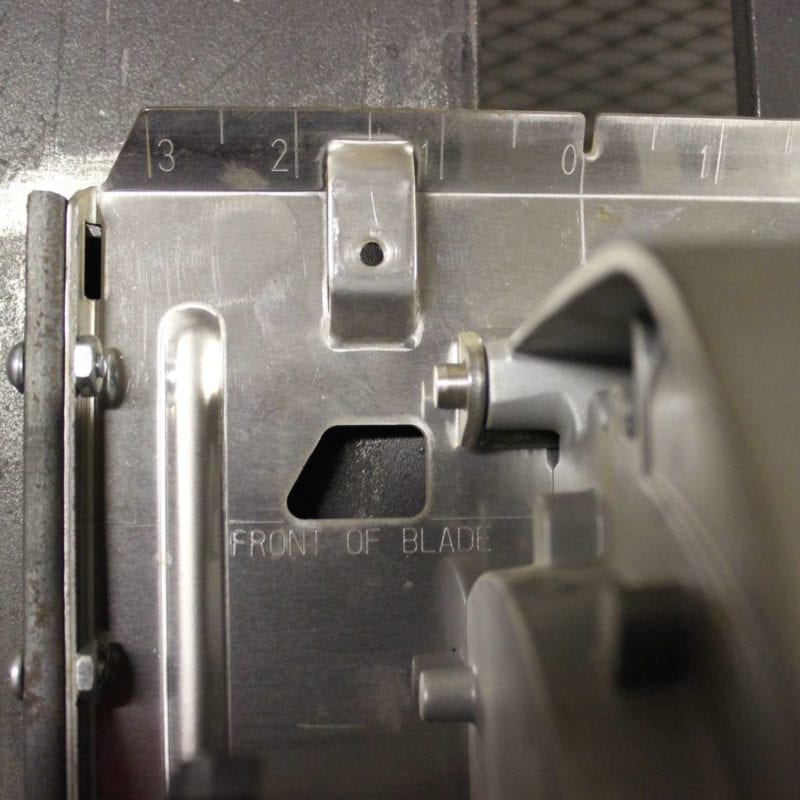

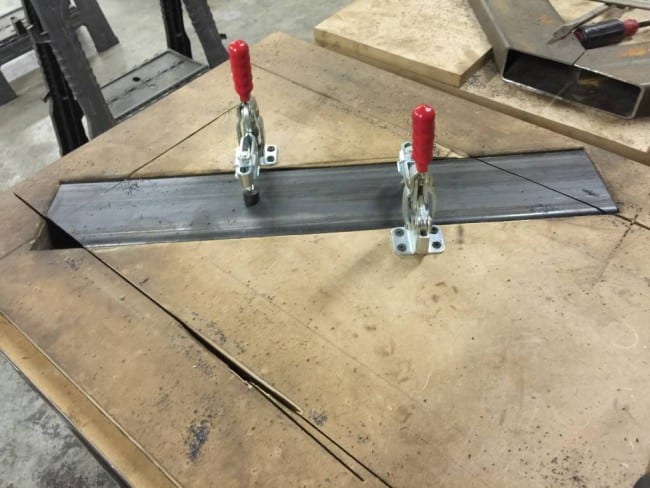

Do you know what’s almost as good as having a CNC router and CNC plasma cutter? Having a good buddy who has one of each! Time to buy him a pizza and finalize my jig design. I settled on making the jig out of MDF and indexing the Milwaukee 6370 to the outer edge of the jig via rip fence, in order to get all three cuts on one cutting jig, as opposed to re-indexing the piece into different cutting jigs. Although the 6370’s shoe has a slot for a rip fence, I modified it to have a slightly more permanent guide. Since this is my primary use for the saw, I drilled and bolted a small piece of flat bar onto the lip of the shoe. This definitely beefs it up, but still allows it to be removed for other applications.

I rough-cut 16 pieces of steel, dropped them into the jig one at a time, clamped them down, and made all three cuts without moving the steel. There were next to no chips or sparks flying around while cutting; the saw felt very clean and controlled. I went through the whole pile in no time, never feeling like the steel or blade was getting hot.

Ergonomics Matter

The handle positions felt comfortable and natural; the plunge lever was awesome—I wish all my circular saws positioned a lever here, and the blade guard has a window into the chip collection so you can see when it’s ready to be emptied out. One other really beneficial feature is the blade point-of-entry indicator. I didn’t want to cut all the way through my jig at the end of the pass, so it was great to be able to glance at the shoe and see exactly where the blade is so that I can stop in time. This isn’t really a necessary feature on a wood saw, since you can see the actual blade. Here it’s a perfect example of the subtle features Milwaukee incorporates into their tool design.

I did everything I could to cut the steel pieces as cleanly and consistently as possible so the four points of the table base rest flat on the floor and bolt flat to the bottom of the table. Sounds easy enough, but it was trickier to implement than I’d anticipated. I honestly believe the Milwaukee 6370 was the absolute best tool for this application and my results agree. Complicated steel table base, cut and welded squarely and evenly: CHECK!