We’ve written about table saw blade height, using miter saws, table saw safety tips, and caring for circular saw blades, but with so many types of circular saw blades available, how in the world do you go about choosing the right one for the job? Even if you know how to use a miter saw like a pro, there are so many blades to choose from. There are blades with many teeth, blades with fewer teeth, blades with no teeth, such as a continuous rim, blades with wide kerfs and thin kerfs, with negative rake angles and positive rake angles, and then blades that claim to be all-purpose, which can be really confusing. So we’ve summoned all of our wisdom and powers of brevity to bring you this useful guide to choosing the right circular saw blade.

Article Summary

- The number of teeth affects both cut speed and how clean the cut is

- Larger blades can have more overall teeth, but the same teeth per inch (TPI)

- Gullet size affects a blade’s ability to “clean out” debris

- Positive rake or hook angles cut more aggressively

- Higher bevel angles produce smoother cuts

- Thinner kerfs cut faster (more efficiently) but may introduce blade wobble

Sink Your Teeth In

The characteristics that determine the function of a circular saw blade are:

Number of Teeth

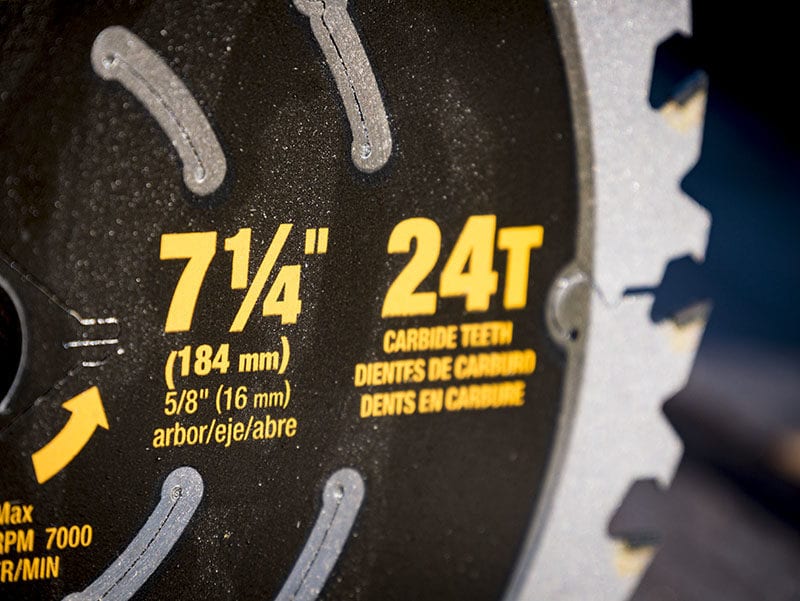

Generally, blades with more teeth will produce a smoother, finer cut, whereas blades with fewer teeth will result in a rougher cut. The benefit of fewer teeth is faster cutting and a lower price. For most construction work, a 24-tooth general-use blade is sufficient. That blade is very aggressive and will help you rip and cross-cut lumber and sheet goods quickly and with a high degree of accuracy. With a 24-tooth demo blade, you’re getting work done quickly, but you won’t get a near-finished edge.

Also, keep in mind that our 24-tooth example is for a 7-1/4″ blade. The same aggressiveness can be found in a 40-tooth blade when you step up to a 12″ miter saw blade. It’s not so much the teeth count as the number and size of teeth per linear inch of the saw blade. Keep that in mind as you shop. A more refined, thin kerf finishing blade is more appropriate when cutting hardwood and trim in scenarios where a cleaner edge is desired.

In general, the higher the tooth count (per blade diameter), the smoother the cut will be. It also means, however, that the saw will need to exert more force, and the cut will be slower on average. For a 7-1/4″ circular saw like the Milwaukee M18 FUEL circular saw, a 40-tooth blade or higher will give you a cleaner cut, but you don’t necessarily want to use that for cross-cutting 2×4 lumber on a job site.

Gullet Size

The gullet is the space between the teeth, the size and depth of which determine how much waste material is cleared out as the blade spins. You can quickly see that the gullet size is a function of the number of teeth.

Hook or Rake Angle

Hook or rake is the position of the tooth as it contacts the cutting surface. A positive angle points down toward the wood’s surface, aggressively removing waste material, resulting in a faster but rougher cut.

Positive hook angles can cause what’s known as a climb cut or self-feeding, as they pull the material in. There are applications, such as metal cutting, where a positive hook can be very dangerous.

As you might imagine, negative hook or rakes cut less aggressively and don’t self-feed, which creates a smoother finish, but they also won’t cut as quickly or remove as much waste. You can find metal-cutting blades and specialty wood blades that utilize a negative rake angle.

The angle can also be neutral.

Bevel Angle

This important distinguishing factor is the angle of the tooth across or perpendicular to the blade’s spin. The higher the bevel angle, the cleaner and smoother the cut. Some blades have very high bevel angles for cutting composite material, such as melamine or other materials with thin veneers that are prone to tearing out/chipping as the tooth exits the material. Bevels can be flat (no angle), alternating, high alternating, or some other configuration that we’ll discuss below.

Kerf

This is the width of the tooth at its widest point and therefore the width of the cut. At first, you might guess that a thinner kerf was designed for finer woodworking, but it was originally developed for less powerful jobsites or portable saws. We reviewed extra-fine, thin kerf 12-inch miter saw blades and found that there is much to be said about the various tooth geometries and vibration reduction technologies used in these blades.

The thinner kerf produced less resistance during the cut and was therefore better-suited for the power needs of those saws. The trade-off, however, was that thinner blades vibrated or wobbled, resulting in cuts that revealed the blade movement. These blades had particular trouble in hardwood cuts.

New blade technology with vibration reduction design has made some improvements in the thin-kerf blade segment (cordless circular saw users rejoice!).

Circular Reasoning

Now that we’ve laid the groundwork, it should be easier to decide what type of blade you’ll want to use for the job at hand. Most importantly, determine what general type of cut you will make – crosscut across the grain or rip cut along the grain. What kind of cut do you need – rough or smooth finish?

These questions are easy to answer with a natural wood whose fibers run in the same direction. Remember, however, that composite materials have no fiber direction—so you’re neither crosscutting nor ripping. It’s also crucial to ensure that the blade you choose is designed for the specific saw type, power capability, and material you’ll be cutting. Choose the right accessory for the job – some types of blades are tool-specific.

Rip Blades

Choosing the right circular saw blade for rip cuts might be even more important. These blades have fewer teeth—typically around 24—and a minimal to no bevel angle. Ripping a piece of wood doesn’t usually require a fine, smooth finished cut. You can save that higher-toothed, higher-beveled blade for the final dimensions later. These blades will clear a lot of material quickly, but it will be rough, which is okay. And this is not to say you couldn’t use an all-purpose or combination 40- or 50-tooth blade for ripping.

Crosscut Blades

Anyone who has used a router on end grain or to cut dados across wood fibers will tell you how the bit causes tearout as it exits the wood (without proper technique or precautions, of course!) Circular blade tear-out is no different. Crosscut blades have a higher tooth count—typically 60 to 100—and a steep bevel angle to prevent tear-out.

Concrete Reasoning?

So while the guidelines above are generally true, they’re not universal. For any kind of rough cutting, such as framing, you’ll find Professionals use a 24-tooth blade for the speed it offers. The wood will be hidden, so there’s no need to create a perfect finish – only a well-measured one.

As the need for a better finish enters the picture, tooth counts should increase. Cutting with a very high tooth count reduces the speed of the cut, but also the tear-out and the amount of finish work needing to be done before you can install the piece.

Bevelatory Idea

We mentioned that the bevel angle is one of the most important considerations in circular blade selection after tooth count. Now, let’s look at the appropriate bevel angle for the material and the type of cut.

Flat Top

These teeth have no bevel angle and outperform many others when clearing a large amount of material for rough cuts, whether ripping or cross-cutting.

Alternate Top Bevel

The teeth bevel in alternating and opposite directions (left/right). This creates a clean cut, with the quality of the cut increasing along with the angle. These blades typically have a mid-range tooth count and make excellent all-purpose blades for both rip and crosscuts. However, keep in mind that hybrids rarely do as good a job as cut-specific blades. Of course, that certainly doesn’t mean you can’t find a blade of this type that you can use for most cuts.

Alternate Top Bevel Raker or Combination

This Alternate Top Bevel blade includes a Flat Top tooth after a grouping of several beveled teeth. As you can imagine, this bevel works well as an all-purpose blade. The Flat Top tooth clears a lot of material with its larger gullets. Additionally, the bevels help it slice cleanly through the material.

Diablo has started experimenting by replacing the flat tooth with a pointed tip for the third grind. Check out our review of their tracking point blade to see how well it works on a framing blade.

High Alternate Top Bevel

As mentioned above, the higher the bevel, the cleaner the cut. These high-beveled blades make very smooth, low-tear-out cuts.

Triple Chip Grind

The blades alternate between Flat Top and a double-beveled or chamfered tooth. These specialty blades work particularly well for hard and composite materials.

Choosing the Right Circular Saw Blade

We hope this article about choosing the right circular saw blade cuts through the confusion so you can select the best accessory for the job. If you’re a Pro and you have circular saw blade selection tips, add them in the comments below – or join the conversation on Facebook, Instagram, and Twitter.