It’s clear people love the idea of products manufactured in the USA. We’ve toured the DeWalt North Carolina manufacturing plant facility, the Milwaukee Greenwood Plant, and the Southwire Wire wire-making plants in Georgia. Our recent KEEN Utility factory tour took us to Portland, Oregon. It let us do something we hadn’t done before: make some work boots! There’s nothing more fun than getting to participate in the process of learning how KEEN work boots are made in the USA. While there, we also took the opportunity to get to know the staff and explore various parts of their company. That included the headquarters, their factory, and even the local KEEN store where they sell products.

Editor’s Note: Check out our best work boots review article for our favorite products for all applications.

How KEEN Utility Work Boots are Made

We got to make KEEN Utility Logandale Waterproof Boots. These are black steel toe boots with a synthetic upper and a direct-attach PU (polyurethane) midsole. This is what KEEN Utility boots look like before assembly (note the uppers shown here are the Braddock):

The first step in the process sorts the incoming boots and shoes so as to correctly place them into the assembly system. Not all KEEN Utility footwear can be assembled here in the United States. An example would be the models with Goodyear welt designs. Those require special double-stitching to attach the sole to the upper.

Each upper is fit to the correctly-sized last. The “last” is the form that represents the proper shoe size (or foot size, really). It makes up the “secret sauce” behind the KEEN fit and allows the consistency you find in every pair of boots or work shoes. KEEN Utility uses a last that is larger in the toe area since they form their protective toes (composite, aluminum, and steel) around the last. Left and right shoes are also uniquely shaped. Many other manufacturers will shave down the toe area to accommodate the extra room required by a protective toe. Others use a single last for both feet.

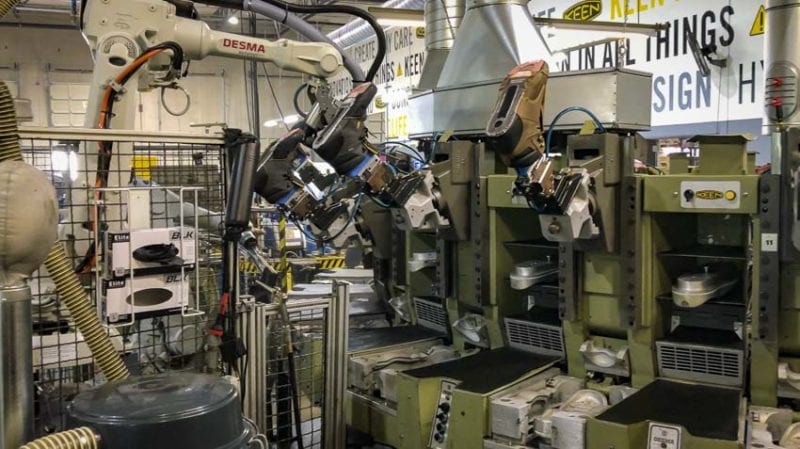

As we participated in the process, our chief job involved taking the uppers, attaching the soles to them, and ensuring proper cleanup and packaging. After placing the uppers of the KEEN Utility Logandale boots onto the correct last, they made their way to a new machine. Here, we saw them prepped, heated, and secured to the midsole/rubber outsole. Before our visit, I thought I could guess how KEEN Utility work boots are made. That guess would have involved either only people….or robots—not both. It turns out both can work in harmony.

Prepping and Attaching the Outsole

The machine occupies a significant amount of space. What might be more impressive, however, is the coordination that goes into making sure everything occurs in sequence. Each upper requires the properly sized last. Each outsole requires a properly sized mold. Everything, of course, must take place in the right order. The floor manager keeps everything on track. Frankly, we think he deserves a raise…

After the automated arms of the machine spray a release agent onto the mold, the system rotates and positions the sole above the mold containing the sole. Once ready, an operator manually triggers the heating element to superheat the sole.

The next step in our KEEN Utility factory tour involved a critical point in how KEEN Utility work boots are made. As we watched, the machine drove the Logandale upper down onto the midsole and clamped down overtop the toe. This locked everything in place and ensured a secure fit.

With the boot now basically formed, it continued on to a brief inspection for any obvious flaws.

Trimming and Cleaning

After we removed our KEEN Utility Logandale boots from the machine, we took them to a new station. There, we manually cut away the excess polyurethane that “squeezed” out the sides as the sole formed onto the boot.

Almost finished! We took the boots to an important station where the KEEN Utility staff showed us how to clean them up. We removed burrs and other imperfections present from the process of applying the outsole.

Finally, we packaged the boots for shipment…we might have had some help here. As it turns out, learning how KEEN Utility work boots are made doesn’t make you an instant expert!

Research, Development, and Testing

Research and development are handled in-house, with Stephen Smith heading up the team as Keen’s Innovation Director. At his disposal is a nifty assortment of 3D printers, vacuum formers, sewing machines, and various cobbling tools, both old and new, to prototype new products and concepts. As an interesting side note, Keen tends to salvage older equipment from other shoe manufacturers and shops, restoring and rejuvenating them for use in their own facilities. It’s a practice that really fits in well with their theme of recycling and making the best use of materials and systems.

The KEEN “Torture Chamber” (Not their Official Name)

Just off the assembly line, our Keen manufacturing tour stumbled upon the “torture chamber”—otherwise known as Quality Control. KEEN examines every aspect of the shoes here. They scrutinize every feature. That includes testing heat tolerance, water resistance, crush resistance, and build integrity. More often than not, Keen’s standards seemed to exceed the industry norms in many areas.

The factory employs a cell-style manufacturing method, and it was interesting to observe the employees working efficiently to assemble the shoes. Another thing that was great to experience was a factory that didn’t have a bad smell. Because they direct-inject polyurethane (PU) to bond the lowers and uppers together, they avoid the harsh chemical glues that could leak out pollutants and render a factory of this size almost unbearable. We were able to walk around and observe everything without masks or any protective equipment. Quite impressive, considering the alternative.

Addressing the Women

Keen realized that women’s feet are generally smaller than men’s. They also have a different shape. To accommodate this, Keen Utility built the women’s line on an entirely different set of lasts than they use for the men’s line. This is a significant difference from simply resizing men’s shoes for women’s feet, and one I’m sure the ladies appreciate.

Reviewer’s note: A “last” is the foot-shaped form used to develop the basic shape of a shoe. It also holds the shoe as it travels through the various assembly stations.

Another Keen tweak is their understanding of the way a safety toe insert affects the fit of a shoe. Most manufacturers offer only three insert sizes to accommodate their wide range of shoe sizes, and typically, these inserts are simply round caps. Keen has 5 different sizes in each of their steel, aluminum, or composite safety inserts, and each one is asymmetrical—left or right—to fit the natural profile of your toes. That’s big!

Wrapping Up Our KEEN Utility Factory Tour

It’s always good to get a feel for how things work. In the case of our KEEN Utility factory tour, we didn’t see hundreds of employees sewing together leather uppers and lacing boots. What we did see, however, was a thriving factory in the heart of Portland that was doing great work. We also saw happy employees. As a business owner myself, that means a lot.

They seem to care quite a bit about quality control, and we’re looking forward to seeing the new KEEN Utility boot styles we previewed in Portland. I’m just glad I didn’t have to sew together leather uppers…the trip might have taken several more days.