If you are Lowe’s and you are working on a new set of mechanics tools, using the Hendrick Motorsports facility as the backdrop for your launch is brilliant. The 100-plus acre Hendrick Motorsports headquarters is located in Concord, North Carolina. The campus is made up of numerous buildings that handle everything that has to do with race cars. Over 500 hundred people work in this location and up to 550 race engines are either built or rebuilt here in a given year. Given Rick Hendrick’s long history of going fast, he has built up the facilities to both house his collections of cars and other motor vehicles and also build some of the most state-of-the-art cars in the business.

Our day started in a presentation room that was set up in much the same way as being trackside. Complete with high concrete barrier walls, guard rails, and protective fencing. One side of the room was arranged to show off the complete line of the new Kobalt mechanic tools, which were actually displayed in much the same way that we would expect to find them in the stores. There were three full racks, complete with all the SKUs, prices, and full retail packaging.

On the other side of the room, there were three completely dissembled Chevrolet R07 racing engines that Hendrick Motorsports builds for their NASCAR vehicles. The gearhead side of me got pretty excited, and I had to exercise extra focus to pay attention to the Kobalt product launch presentation. Lowe’s could not have found a more fitting place to launch a line of mechanic’s tools than a facility that really takes wrench turning seriously.

Hendrick Motorsports Event

The relaunch of the Kobalt mechanics tools really came after the realization that the current line of tools did not meet the needs of the consumer. It was difficult to replace individual items because they were only sold in sets and, frankly, they lacked many professional grade enhancements. Lowe’s design and marketing staff quickly honed in on what their customers were interested in and it was found they wanted MAC quality and features for Lowe’s prices.

This was a lofty goal and, in part, where the mechanics, and staff at Hendrick Motorsports came into play. Lowe’s solicited the advice, input, and car building experience from the guys at Hendrick to develop a very exciting new line of products that really are targeted at the guy that needs to depend on his tools for his livelihood. We are talking about real mechanics and car guys. Lowe’s would like to think of it as moving beyond serving just the needs of DIY types and into the world of professionals with their new mechanics’ tools.

User Feedback and Warranty Replacement

Based on what the professionals expect from their tools, Lowe’s started from scratch and came up with not only tools but a new support program to ensure that you have a better experience with their products. With a real “no questions asked” return policy, you can walk into a store with a broken socket or wrench, find the replacement and walk out… well, maybe after checking into the front desk first. In addition to a real lifetime warranty, they are offering, for the first time ever, “Sockets for Life”. What this program does it that it allows you to register your tools with Lowe’s. Then, if you have a socket that gets lost or stolen, simply call them up and they mail you the new item for a very nominal shipping fee (they were estimating $4 or $5).

Assembling an R07 Engine Using Kobalt Tools

Once we were done with the introductions to the new Kobalt tools, we were ready to get our hands dirty putting the R07 engines together using only Kobalt Tools. They divided us up into three groups of 4 or 5 and had us pair up with some of the professional engine building and tuning staff from Hendrick to guide us through the whole build process. With the engine block already mounted on a stand, the rest of the parts were laid out on three tables.

We started off with the bottom end and put in the main bearings, laid the crank in place and put on the main caps. I have rebuilt and replaced engines in the past, but nothing was quite like this. To a gear head, the engine parts that were strewn around the room looked more like jewelry than car parts. Many of the parts are mirror polished and every part has had all the sharp edges removed. We continued with the build and put in the pistons, oil pan, heads, lifters, rocker arms, intake and the rest of the parts that go into a motor to make it work.

Using only Kobalt tools in the build proved to be a success since they had every kind of tool needed, including various torque wrenches, speed bars, extensions and specialty sockets.

Firing Up a $70,000 Engine!

As if it was not enough to build up a $70,000 dollar engine, when we were done, we pushed it outside and actually started it up and let it run for a few minutes. The thunderous noise from the exhaust as I worked the throttle put a permanent smile on my face for the rest of the day. To think that they are able to crank out 820 horsepower from that small block V8 is amazing!

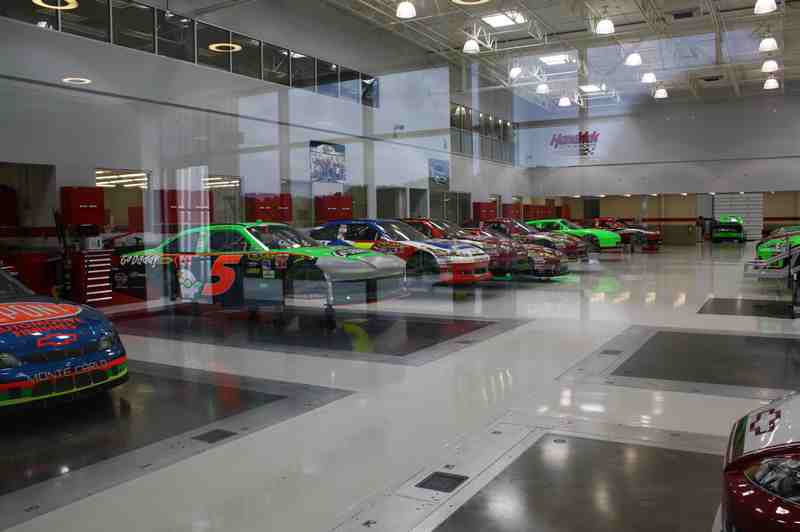

Hendrick Motor Sports Facility Tour

To continue our day, we got an inside tour of the Hendrick Motor sport facility. You might be wondering about the lack of photos for this part of the tour, but we were told early on that if we as so much lifted a camera to take a photo that someone from the garage would tackle us football style. Since all the areas we visited are part of the working shops that build both the cars and engines, Hendrick takes it serious that we didn’t disclose any secret or experimental car building they might be working on. We were, however, given some photos from Hendrick which we included here.

The biggest thing that jumped out at me was how clean the entire facility was. This was not your typical car shop, there is no grease or oil stains, the bench tops were cleaner then my kitchen counter and everything had a polished look to it.

With the bright lights and light gray floors and specialty equipment everywhere, it was more inline with a sterile surgery center. Hendrick Motorsports has the space and facilities to handle every aspect of the cars they they build. All the way from bending the tubes to making the frames, to the sheet metal shop, paint booths and graphics areas.

Machining the Blocks and Testing

On the engine side of things, they have the ability to machine and finish the rough castings they receive from GM to make the blocks, heads and intakes. In-house they have full machine shops and testing equipment that lets them keep super tight quality control on every aspect of the car.

What was cool to see is that not only is Hendrick Motorsports all about the cars, they are about the people that build and race them. With full gym and workout areas on campus, they make sure that the pit crews are ready for lightning fast pit stops. There is both a public museum and gift shop and Mr. Hendrick’s private museum as well.

Jimmy Jam!

As if this was not enough to check out the inner workings of Hendrick Motorsports, we finished off the night with the Jimmie Jam where we had the chance to meet Jimmie Johnson, driver of the Hendrick Motorsports, Lowes # 48 car along with Montgomery Gentry and Randy Montana. While I might not be a die hard NASCAR fan yet, I am starting to come around to realizing that it is not a group of rednecks making a bunch of left hand turns for a few hundred miles.

The inside tour at Hendrick helped me see that not only is there the spectator sport aspect to racing, but there is an amazing support structure that goes behind it. With literally hundreds of people in the background making the cars run better, longer, stronger and all the while using tools to make it happen.